POLYRACK

Role: Designer

Team Members: Sophie Weissel, Anastacia Devlin

Advisor: Kevin Shankwiler

Duration: 5 Weeks

Prompt: Design a sporting good utilizing the thermoplastic composite, Polystrand.

WHAT IS POLYSTRAND?

Polystrand is a continuous fiber-reinforced thermoplastic composite that has properties as follows:

Strength-to-weight ratio rivals many metals.

Resistance to UV light, chemicals, moisture degradation and rot resists wear and tear.

Impact resistance for durability.

Ease of re-forming, reusing, recycling for sustainable usage.

Strong adhesion to other materials for various combinations.

Unidirectional bending for unseen applications.

WHY PURSUE THE BIKE INDUSTRY?

01

Potential for thermoforming

02

Customization opportunities

03

Weight and durability are important

04

Innovation is constantly revolutionizing the industry

RESEARCH/INTERVIEW SYNTHESIS

Bikepacking is a subset of mountain biking which combines riding on off-road trails, long-distance biking, and camping. Because of the physically taxing nature of the activity, it is best practice to keep the load as light as possible while also carrying all necessary gear for the journey.

Carrying gear and supplies is integral to a successful and fun bikepacking trip.

Our goal as designers was to determine how to enhance the gear-packing experience utilizing the unique properties of Polystrand.

to get to a different location

to exercise

to enjoy a part of their routine

to be a part of a biking community

to challenge oneself

to achieve self-efficacy

to save time and effort

to be a part of different groups

to be self-sufficient

to provide

for loved ones

Amateur

Hobbyist

We decided not to pursue amateurs as our target user because they are less apt to go out of their way for a useful bike product. They see their bike more as a tool than something to invest in.

We chose to pursue hobbyists because of their invested emotional connection and time to their bicycle. They are more likely to search for a bike accessory or add-on, depending on their particular interests.

HOW MIGHT WE...

...distill necessary yet unobtrusive gear

...enhance riders’ safety in isolated or emergency situations

...maintain the “coolness” factor

CONCEPT DEVELOPMENT

These sketches focused on different methods of attachment that involve tubular metal for support and structure instead of relying on the inherent qualities of Polystrand. We also chose a more rigid form that involved thermoformed bends.

We decided not to pursue a design with more structure so we could showcase and celebrate Polystrand and its uniqueness.

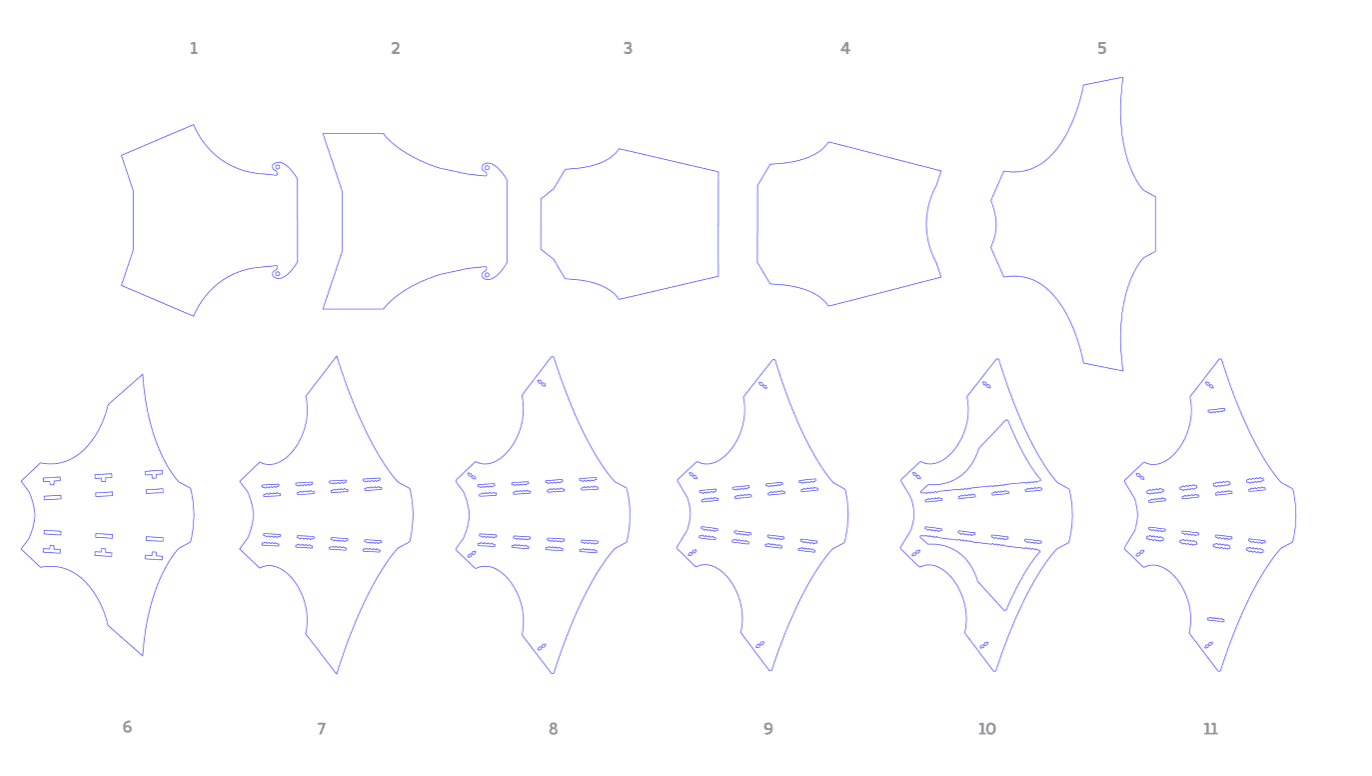

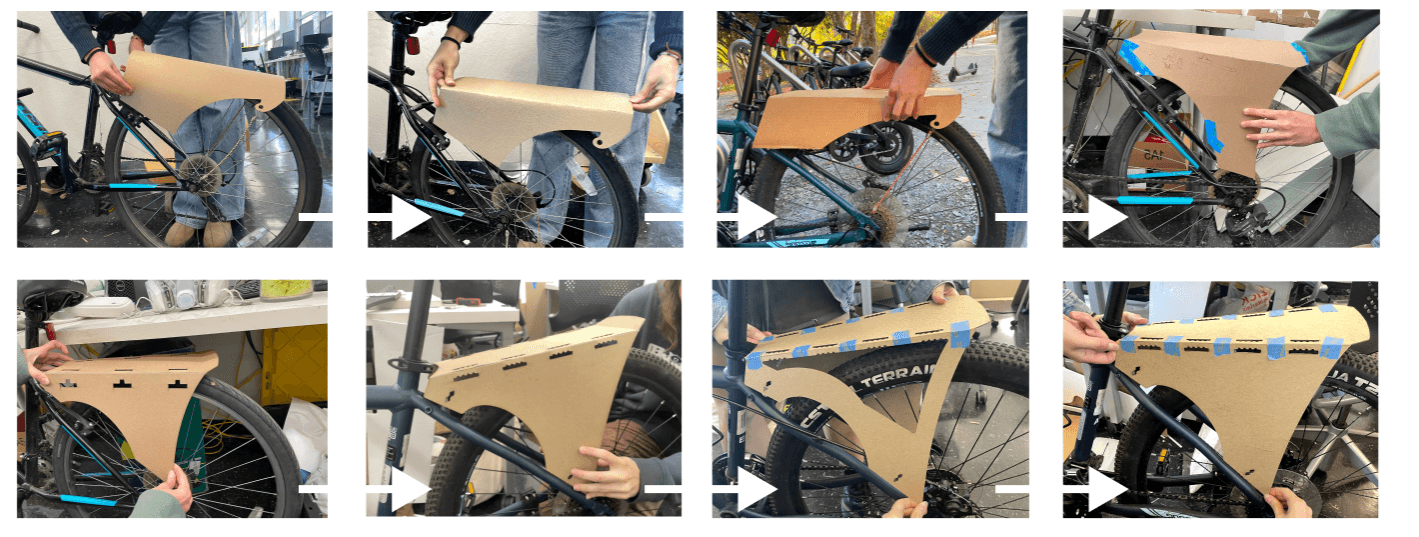

ITERATIVE LASER CUTTING TEMPLATES

We laser cut different iterations of shapes and sizes, tested them on the bike, and made changes based on our findings. This helped us determine the best types of fasteners, external attachment points, weight distributions, and angles.

RESEARCH THROUGH DESIGN

FASTENERS